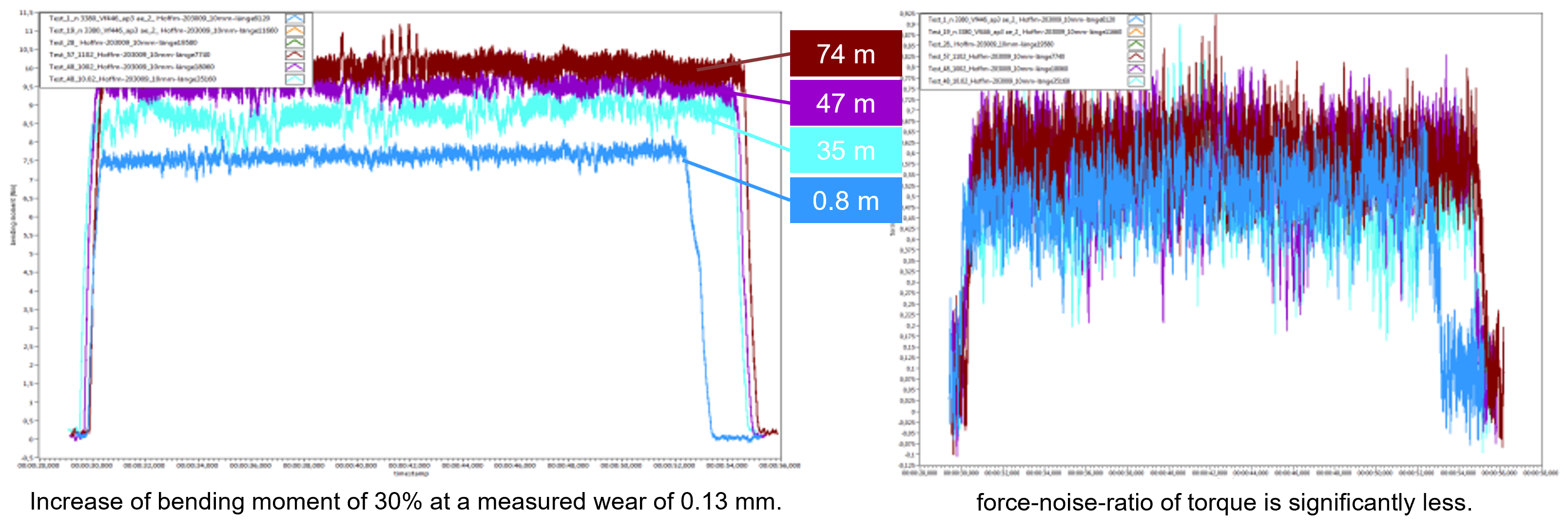

How to judge if the tool is worn?

此處可至後台加上本圖片的描述

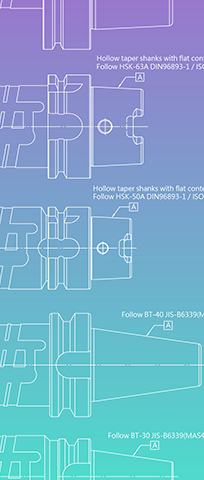

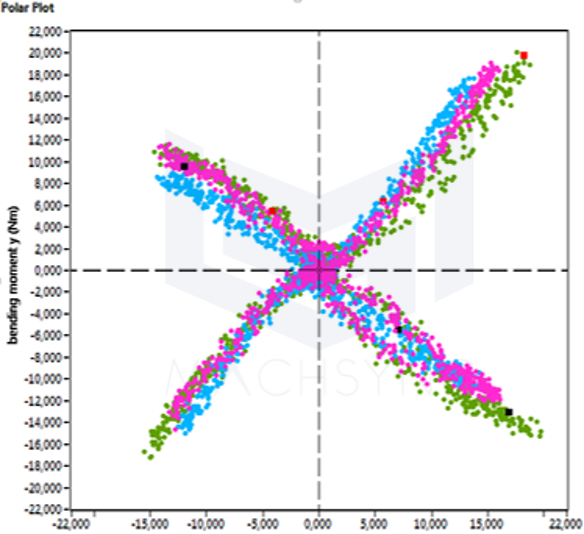

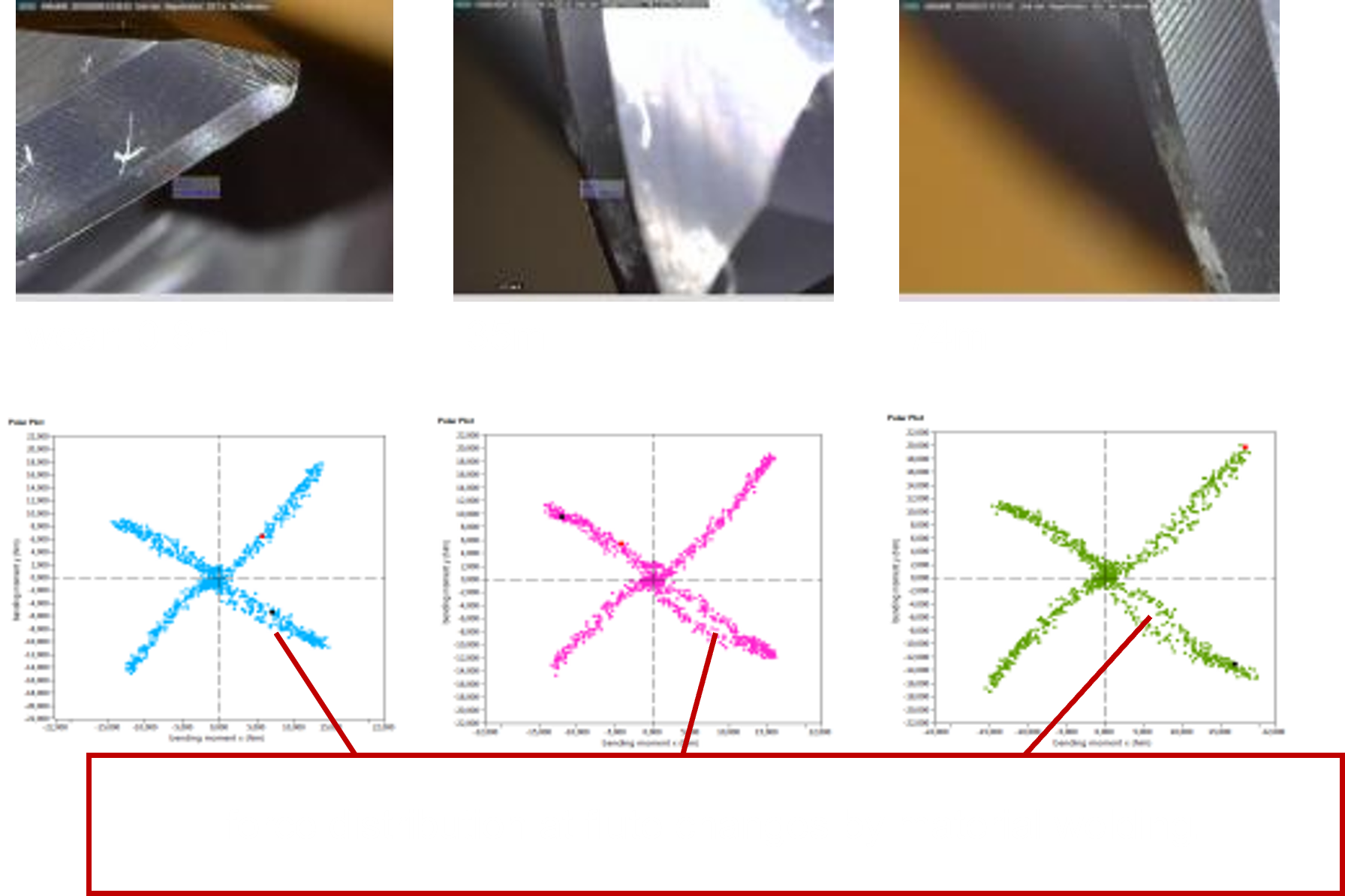

For example, unsuitable tools or materials will gather chips or sticky chips during the cutting process. From the above graph, we can see the symmetry of the four edges. The lower right side with higher cutting force produces a signal that like Rib Eye due to sticky chips.

Such signal not only causes poor chip evacuation at this cutting edge but also increases the temperature, which means that the tool life of this cutting edge will become very short. Therefore, from the polar plot polar above, the machine tool master can clearly judge whether the parameters need to be improved or directly replaced with a suitable tool.