What is wear and tool life?

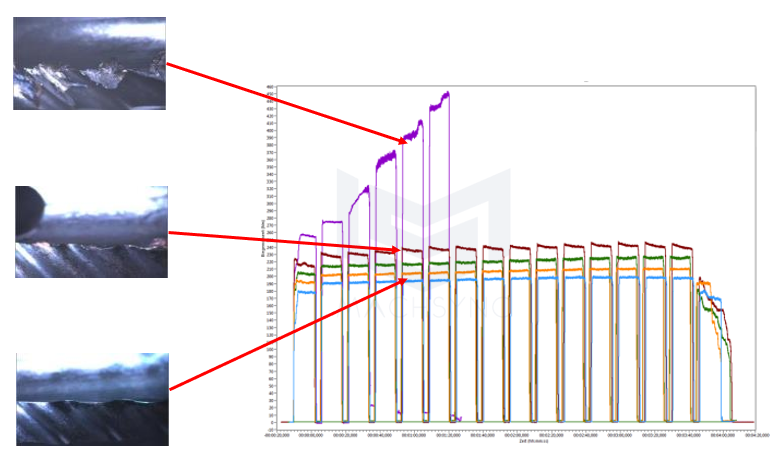

During the cutting process, the combined result is generated by the physical and chemical action of heat and friction, called “tool wear”.

The cutting time passing by before tool damaged is known as “tool life”.

The predetermined value of the tool wear level is mainly used as the judgment basis. In production, the life and working hours are often determined according to the processing conditions.