What is Digital Twin?

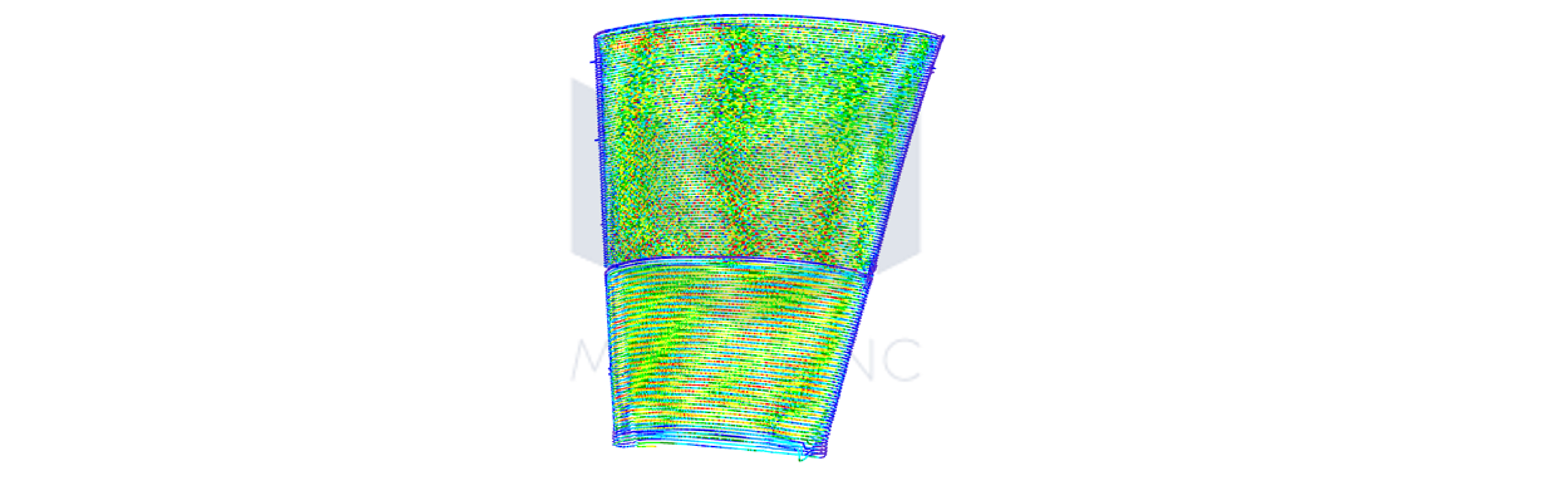

Digital Twin refers to the establishment of a digital analogy by integrating physical feedback data and through Artificial Intelligence, machine learning and software analysis. And this can be applied in various industries, which can shorten product development cycle and cost, reduce maintenance cost, and enhance the service quality…etc.