What Is Friction Stir Welding?

Friction stir welding (FSW) is a joining process technology originally invented by the Welding Institute in the United Kingdom in 1991. Different from traditional welding methods, this method can form defect-free high joining quality and obtain good welding quality also mechanical properties.

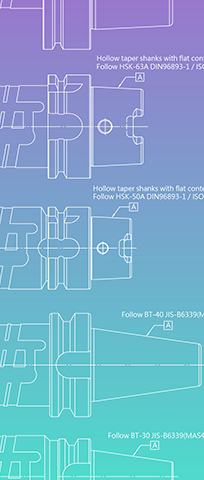

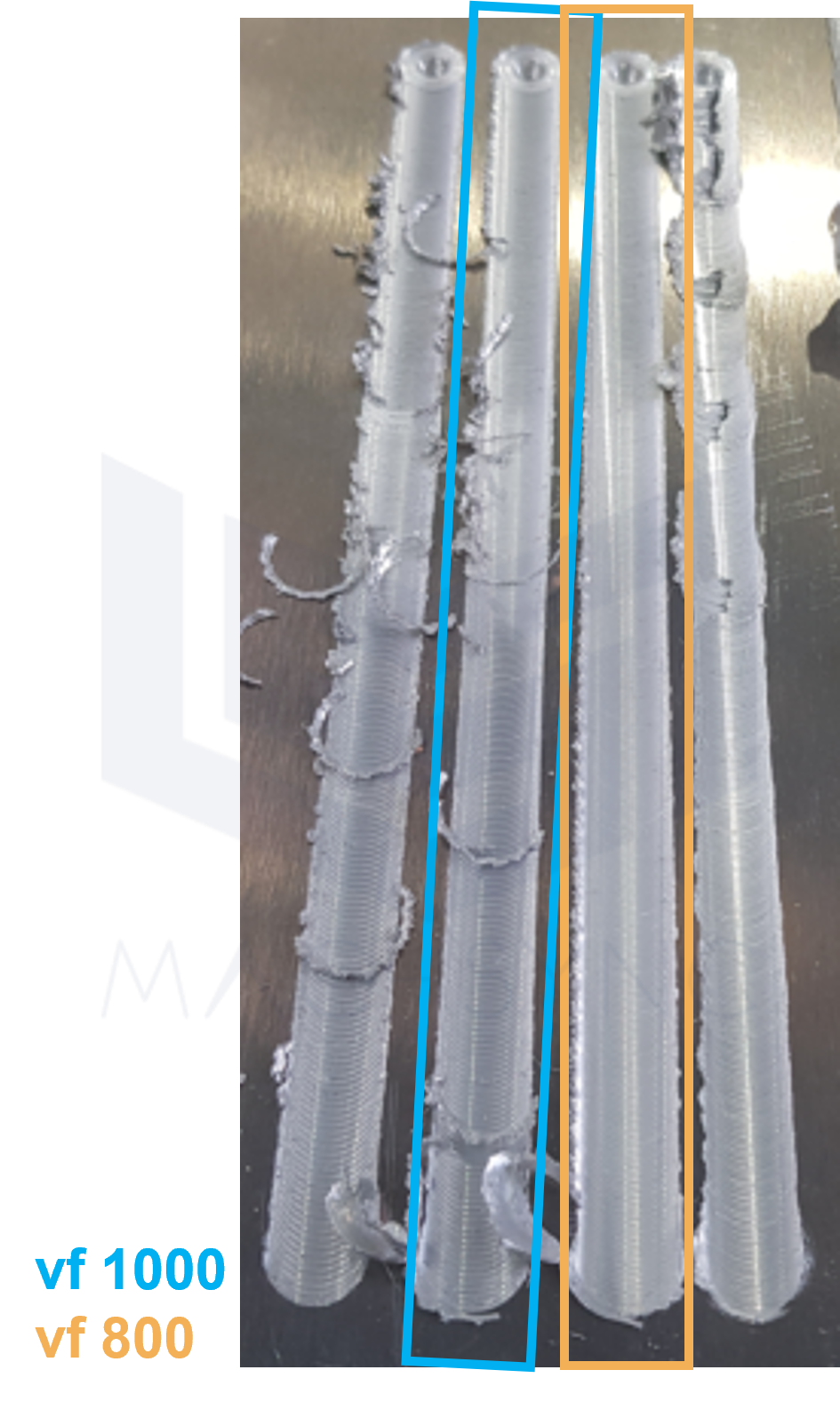

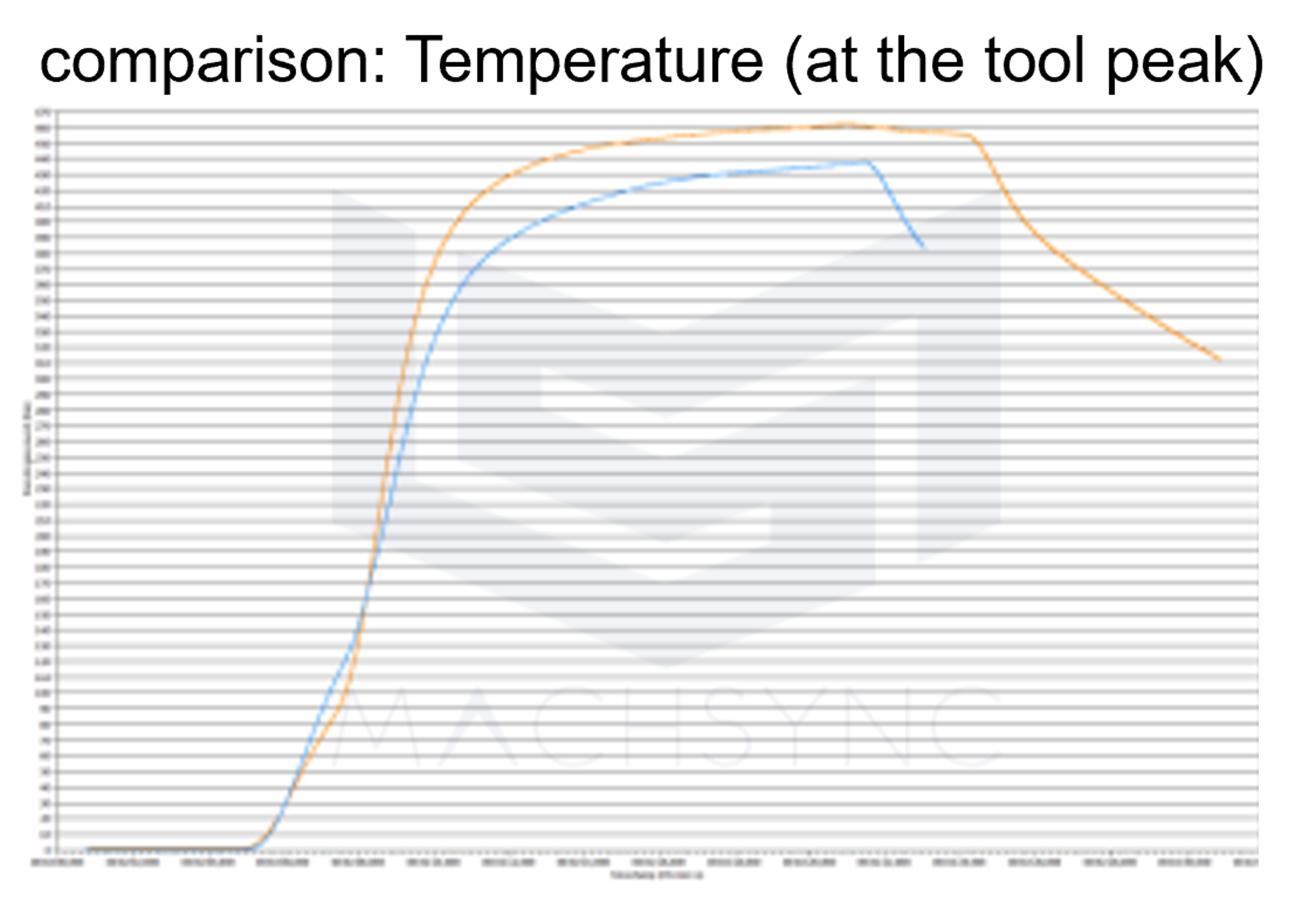

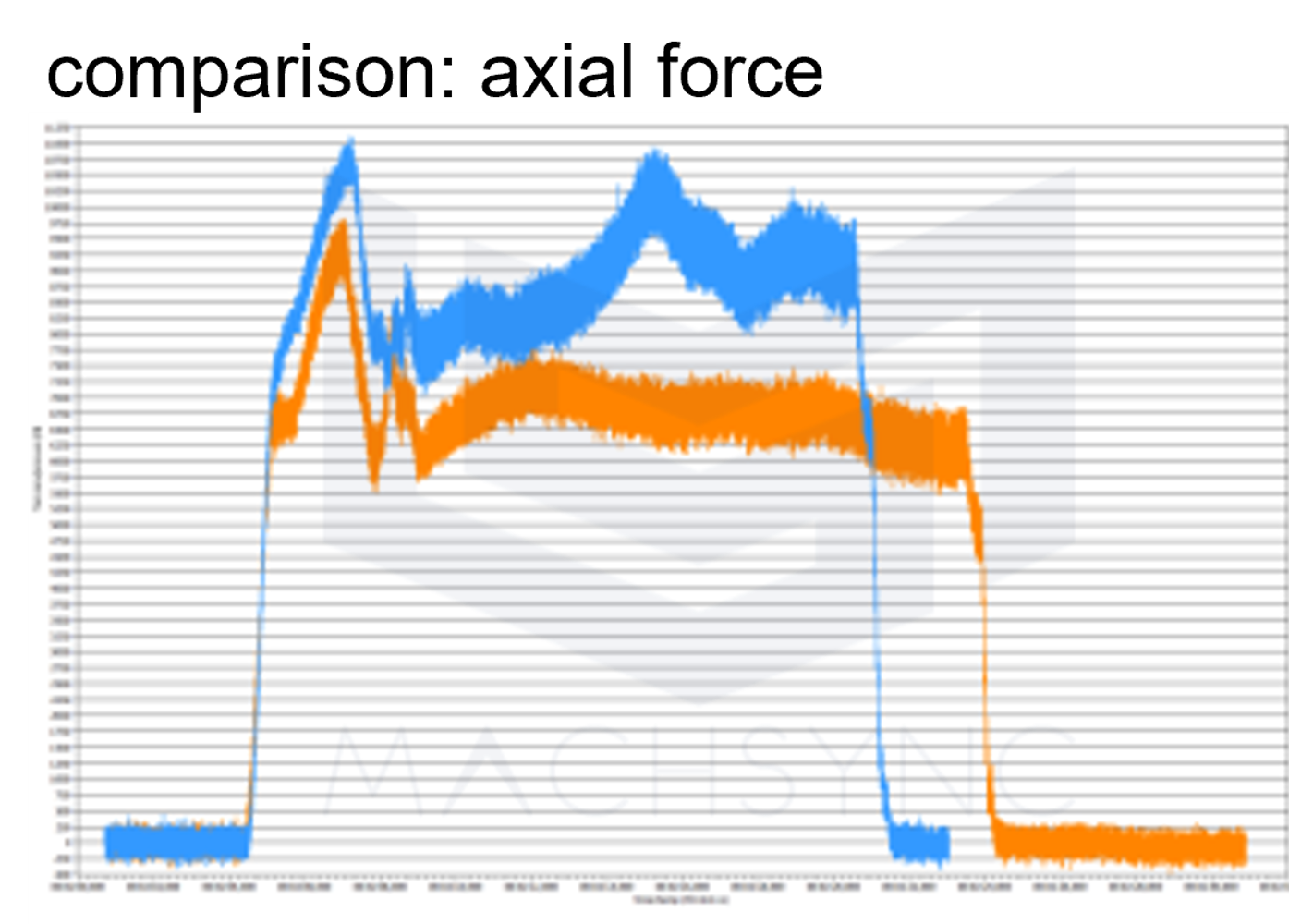

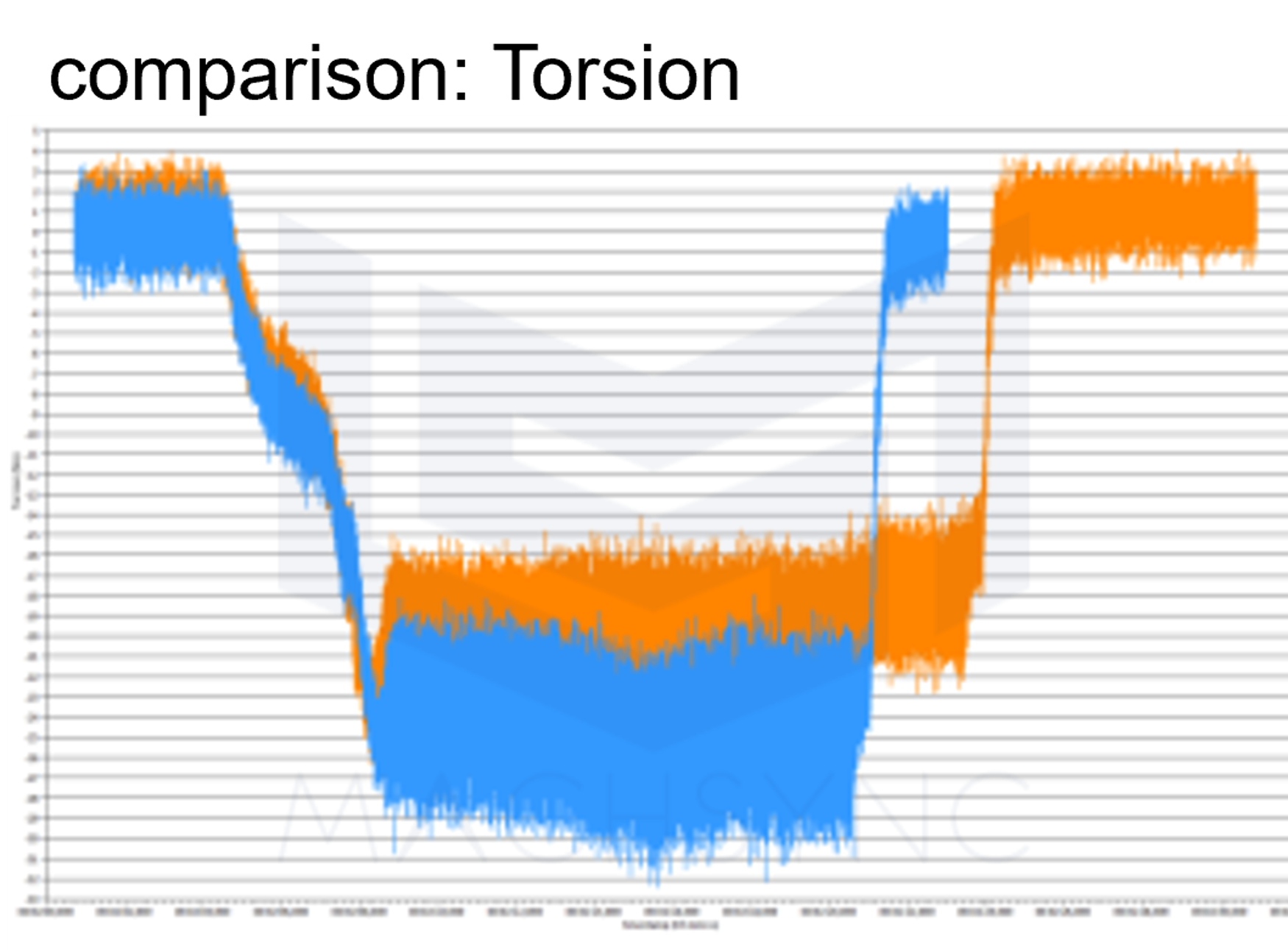

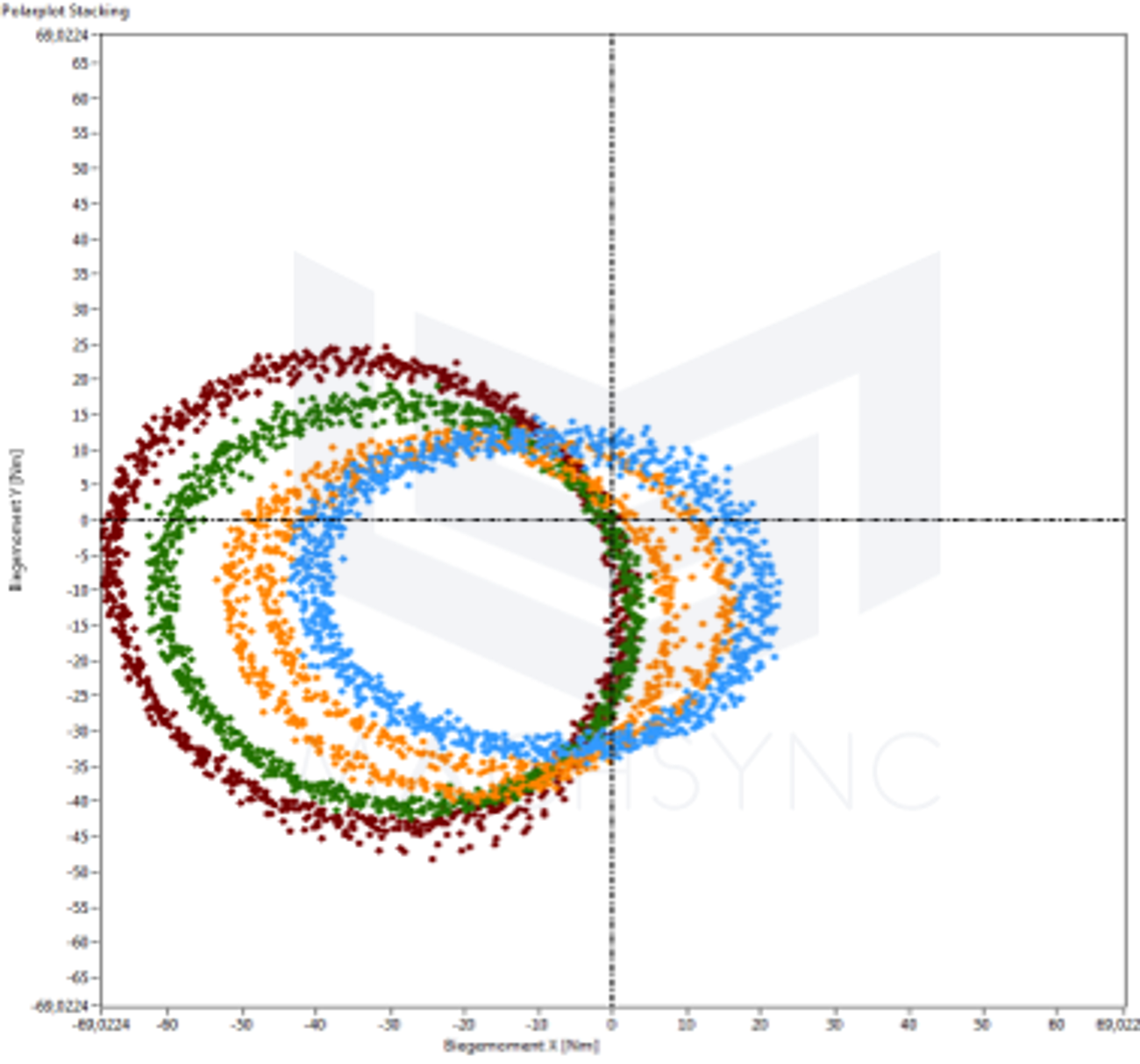

The welding of FSW is when a cylinder tool or other shape (with a spiral cylinder) is inserted into the joint of the workpiece, and the high-speed rotation of the welding head rubs with the welding material so that the temperature of the material in the joint increases then softens the material, and at the same time, the material is subjected to friction stir welding to complete the welding.

This technology is especially suitable for joining low-melting non-ferrous metals and mixed joints, such as aluminum, magnesium, copper, titanium or steel, and other difficult-to-weld materials.