Grinding and Grinding Wheels

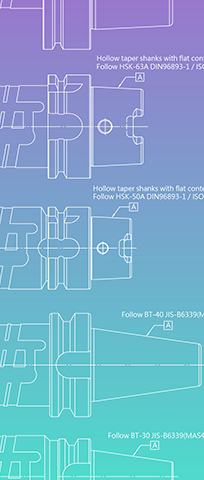

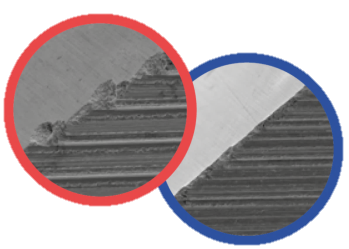

Grinding is a machining method. Different from cutting, grinding uses a "grinding wheel". Using the abrasive particles on the tool to process the surface of the workpiece under a certain pressure, the composition of the grinding wheel consists of three major elements, abrasives, binders, and pores, they all have different functions.

Abrasive is the part that directly cuts the workpiece, the binder is attached to the abrasive, and the pores can dissipate heat and remove chips. In the action of grinding, the mechanism overcomes the chain force inside the solid material, and the size and shape of the ground material will change.