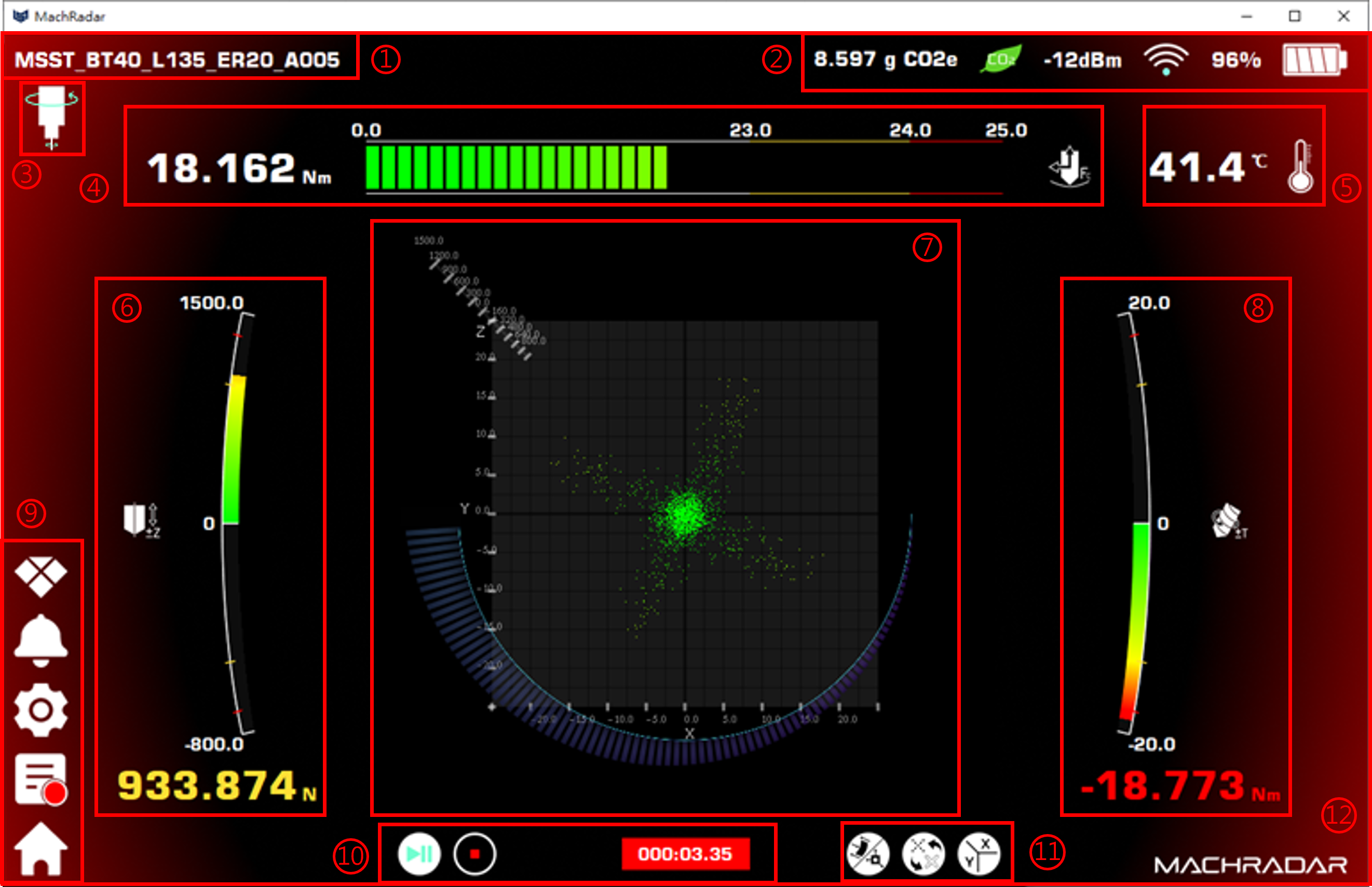

1. Smart Tool Holder Menu: Manage the registered smart tool holders in the tool library and monitor the health data of the matched tool sets by tracking their identity and related parameters.

2. Smart Tool Holder Connection Information: Intuitive status display similar to a mobile phone that provides real-time signal service, battery life, and carbon emission data of the current process.

3. High-Speed Rotation Monitoring: Visual pattern indication of the smart tool's high-speed rotation.

4. Cutting Force Status Information: Real-time cutting force during machining with the warning (yellow) and alert (red) values can be freely set for immediate control of any emergency within 0.001 seconds.

5. Temperature Status Information: The real-time temperature of the smart tool holder during machining can be calculated to display the trends of whether there is reasonable heat dissipation or the use of proper cutting fluid during machining.

6. Axial Force Status Information: Real-time axial force during machining with the warning (yellow) and alert (red) values can be freely set for immediate control of any emergency within 0.001 seconds.

7. Galacsync 3D Status Information: Comprehensive analysis of all physical cutting forces to intuitively restore the cutting profile of the tool and quickly identify any abnormal causes during machining.

8. Torque Force Status Information: Real-time torque force during machining with the warning (yellow) and alert (red) values can be freely set for immediate control of any emergency within 0.001 seconds.

9. Function Menu: Functions buttons for selecting modes, events, viewing settings, scripts, and the home page.

10. Connection and Recording Buttons: Connect and record the machining data of the smart tool holder.

11. Display Settings: Switch between machining information and three-axis information display, data plotting styles (dots or lines), and restore the default angle plane view.

12. Background Warning Colors: Emphasizes warning (yellow) or alert (red) values with a background color.